Electronics, The latest trainings

Understanding DIP ICs Where and When to Use Dual In-line Package Integrated Circuits

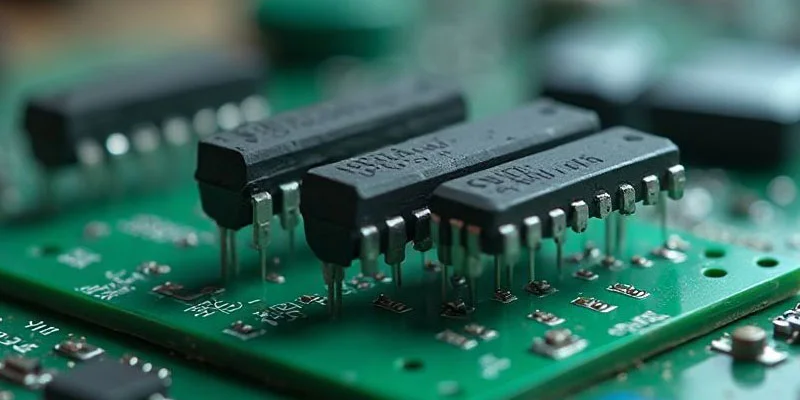

In the world of electronics, integrated circuits (ICs) come in many different packaging types. One of the oldest and most widely recognized is the DIP (Dual In-line Package). Although surface-mount devices (SMDs) dominate modern electronics, DIP ICs continue to play an important role in prototyping, education, and certain industrial applications. This article explores what DIP ICs are, their structure, benefits, drawbacks, and when to choose them over other packaging types.

What is a DIP IC?

A DIP IC (Dual In-line Package integrated circuit) is a type of chip package where the pins extend from two sides of a rectangular housing. These pins are usually spaced at 0.1 inches (2.54 mm), making them compatible with breadboards and through-hole PCBs.

DIP ICs were introduced in the 1960s and became the standard for integrated circuits for decades. Popular microcontrollers, logic chips, and memory chips were originally released in DIP form before transitioning to SMD packages.

Key Features of DIP Packages

-

Pin Layout: Two parallel rows of pins, typically between 8 to 64 pins.

-

Material: Usually plastic or ceramic encapsulation.

-

Compatibility: Fits into IC sockets, breadboards, and through-hole PCBs.

-

Size: Larger compared to SMD, making manual handling easy.

Advantages of DIP ICs

-

Ease of Prototyping – DIP chips are ideal for breadboards and socket-based circuits.

-

Beginner Friendly – Electronics students often start with DIP ICs because they are easy to solder and test.

-

Durability in Handling – Larger size makes them less prone to mechanical damage during assembly.

-

Reusability – Can be easily removed and reused from circuits.

-

Cost Effective for Low-Volume Projects – Cheaper tooling costs compared to SMD in small production runs.

Disadvantages of DIP ICs

-

Bulky Size – Takes up more board space compared to compact SMD packages.

-

Limited Pin Count – Usually not available beyond 64 pins, unsuitable for high-performance modern ICs.

-

Lower Suitability for Mass Production – Automated assembly lines prefer SMD packaging.

-

Signal Limitations – Larger lead lengths cause signal delay and are less suitable for high-frequency circuits.

Where Should DIP ICs Be Used?

1. Prototyping and Education

DIP ICs are perfect for breadboard-based projects, school labs, and rapid prototyping. Their ease of insertion and removal makes them ideal for learning environments.

2. Low-Volume Production

For small production runs or DIY electronics kits, DIP ICs are more cost-effective since they don’t require advanced SMD soldering equipment.

3. Socketed Applications

In designs where IC replacement is expected, such as EPROMs or microcontrollers that need frequent updating, DIP ICs in sockets make maintenance much easier.

4. Industrial and Legacy Systems

Older equipment still relies on DIP ICs. Engineers often use them for repair, maintenance, and compatibility with legacy boards.

5. Hobbyist Electronics

Makers and hobbyists often prefer DIP ICs because they are easy to solder by hand without advanced reflow equipment.

Comparison: DIP vs. SMD ICs

| Feature | DIP ICs | SMD ICs |

|---|---|---|

| Size | Larger | Much smaller |

| Ease of Handling | Easy | Requires skill |

| Prototyping | Ideal | Difficult without adapters |

| Production Volume | Better for small runs | Best for mass production |

| Performance | Limited | Supports high-speed circuits |

Future of DIP ICs

While DIP ICs are no longer dominant in consumer electronics, they continue to serve a valuable niche in education, prototyping, and industrial maintenance. As long as electronics enthusiasts and repair engineers exist, DIP packages will remain relevant.

Conclusion

DIP ICs may feel outdated compared to modern compact packages, but they remain essential in many scenarios. They are unbeatable for prototyping, education, and applications requiring easy replacement. Knowing when to use a DIP IC versus an SMD package can save time, money, and effort in both small-scale and industrial projects.

For students, hobbyists, and even professionals, DIP ICs will continue to be a reliable choice for years to come.

Join our newsletter to get the latest projects, tutorials, and tech updates straight to your inbox! 🚀