Robotics articles, The latest trainings

Best Balance Sensors for Robots | Gyroscope, IMU & Tilt

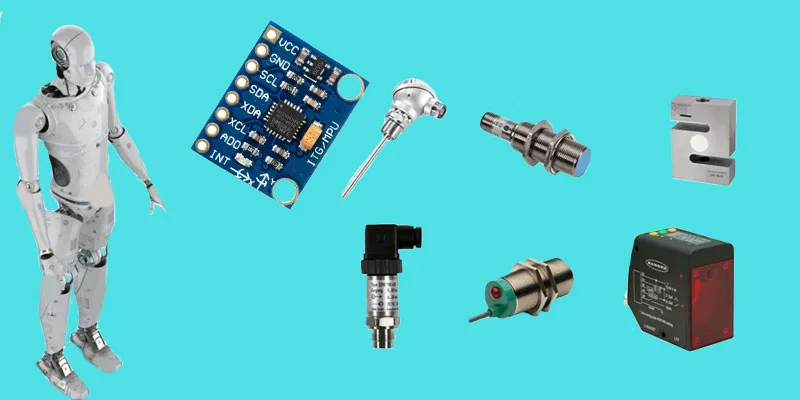

For robots that require balance, motion and balance sensors are essential. These sensors provide real-time data on angles, acceleration, and orientation, allowing the controller to adjust movements and maintain stability. Choosing the right sensor improves precision and stability for two-wheeled, flying, and industrial robots.

1. Gyroscope

Function: Measures rotation rates around X, Y, and Z axes to detect changes in direction.

Recommended Models:

-

MPU-6050: Combined gyroscope and accelerometer, ideal for balancing robots.

-

L3G4200D: High precision, suitable for drones and professional projects.

2. Accelerometer

Function: Measures linear acceleration and gravity direction to detect tilting angles.

Models:

-

ADXL345: 3-axis, perfect for stabilization and balancing.

-

MMA8452Q: Sensitive and accurate, for educational and lightweight industrial projects.

3. Inertial Measurement Unit (IMU)

Function: Combines gyroscope and accelerometer (sometimes magnetometer) for complete motion and angle data.

Models:

-

MPU-6050: Ideal for small and two-wheeled robots.

-

MPU-9250: Suitable for robots requiring precise navigation.

4. Tilt Sensor / Inclinometer

Function: Detects tilting angles or slope of the surface; simple and cost-effective.

Models:

-

SW-520D: Digital tilt sensor, great for educational projects.

-

ADIS16209: High-precision analog sensor for industrial robots.

Applications

-

Two-wheeled robots: MPU-6050 or ADXL345 for angle control and balance.

-

Flying and industrial robots: MPU-9250 or L3G4200D for fast motion and precise navigation.

-

Simple educational projects: SW-520D tilt sensor.

Using these sensors correctly improves robot balance and stability and lays a foundation for professional and advanced robotics projects.